- Stihl MS 250 Carburetor rebuild kits are made up of gaskets, diaphragm (rubber or viton material), a fulcrum (metering lever), a fuel inlet screen, a metering lever rod, and welch plugs.

- The carburetor on a Stihl chainsaw channels a mixture of two-cycle oil and gasoline into the engine.

- At this point we should have done a thorough inspection of all the parts that we systematically removed to determine which parts need simple cleaning or total replacement with brand new parts. Then the rebuilding begins.

- The Stihl MS 250 carburetor has two different sides. Side A is the fuel pump side of the carburetor.

There is a relatively simple and economical way to clean out a carburetor on any Stihl chainsaw.

Table of Contents

ToggleStihl MS 250 Carburetor rebuild kits are made up of gaskets, diaphragm (rubber or viton material), a fulcrum (metering lever), a fuel inlet screen, a metering lever rod, and welch plugs. As you use your machine, and due to normal wear and tear, the diaphragms in the carburetor will get hard, crack or become distorted as a result of ethanol gasoline. When this happens, the carburetor must be cleaned and a new Stihl MS 250 carburetor kit installed. The carburetor can as well get contaminated with water, causing white rust. The Stihl MS 250 carburetor rebuild kit will be necessary.

How to rebuild Stihl MS 250:

The carburetor on a Stihl chainsaw channels a mixture of two-cycle oil and gasoline into the engine. That mixture, plus dirt or debris that makes its way past the air filter, can cause a gummy sticky mess that will affect the proper function of a carburetor. In time it can cause engine damage. There is a relatively simple and economical way to clean out a carburetor on any Stihl chainsaw.

When engine damage occurs, you will have to come to grips with how to repair a Stihl chainsaw. Before you rebuild your Stihl MS 250, you’ll first have to tear it down. Here’s a step by step process on how to tear down and how to rebuild Stihl MS 250.

- Open the exhaust screws in order to look at the piston and the cylinder. The exhaust is fixed with 2 studs.

- Open it on the admission side. Remove the lid, the air filters (it’s fixed with 2 screws)

- Remove the carburetor. This should come off easily. Open the shock and remove the acceleration leverage. To remove the acceleration leverage, press on the trigger. Now it can be easily removed.

- Remove the plastic part. We will open its spark plug too. But before that, open the shock absorbers. Open the shock absorber from the front. Remove the outer lid. Open the bottom part of the shock absorbers, this is normally secured by 2 screws.

- You are now face to face with the inlet gallery. Open this as well. Be careful not to break it.

- Open the outer shock absorber. Since it just needs loosening, you can use a screw driver here. Be careful not to damage the shock absorbers as you remove them.

- Remove the ignition wires. Now the plastic cover should come out easily.

- Now you should have access to the motor. Clean the motor. Check for any wear and tear.

- Next open the starter which is fixed with screws.

- Open the outer shock absorber and remove the brake.

- Now remove the handle. This should give you access to the cylinder. Clean the cylinder. There are normally 4 screws that hold the cylinder. After they are all removed, the cylinder should be detached.

- Open the ignition wire. The cylinder can now be removed. Lookout for any metal fillings. The crankcase and the piston should be visible to you now. Inspect them for any damage. Needle bearing should also be visible to you. Inspect it for any damage.

- Open the safeties, the piston bolt and remove the piston. You will need some force to remove the piston. Inspect the piston and the needle cage.

- Open the flywheel. Open the lip to get to the side clutch to access the crankshaft bearings.

- Open the safety, the flat washer and then the pot to create space. The pot most likely needs cleaning.

- Remove the needle bearing and open the clutch.

- Remove the rear from the oil pump. Open the flywheel and remove it (you may need to use a press). Open the ignition. Remove the lid from the cylinder and the crankshaft. Inspect the crankshaft, the cylinder and its cap to determine if they need cleaning or replacement.

- At this point we should have done a thorough inspection of all the parts that we systematically removed to determine which parts need simple cleaning or total replacement with brand new parts. Then the rebuilding begins.

- With your new parts, first the bearing then the seals and place them on the chain saw.

- Place the piston, the bearing and other parts in their place.

- Now place the cylinder back to its place. With the piston already on the cylinder, it will be easier to place. Tighten with the 4 screws.

- Place the flywheel, fix it in place with a nut. Then proceed to the ignition. Use an A4 paper folded in 4 to adjust the ignition distance.

- Now turn to the clutch side. Place back the pot, needle cage, flat washer, safety and the lid.

- Place back the handle and the plastic cap. Fix them with screws. Place carefully the inlet gallery. Place the starter and the 4 screws back.

- Place back the carburetor, the ignition, the acceleration leverage, the spark plug, the protection and air filter. Tighten with screws. Place the plastic cap back on. And the exhaust. Fix them with their studs.

- With everything back in place, we need to check the compression of the engine using the compression clock. This is fixed where the spark plug usually sits. Fire the engine. Make sure in your test, the acceleration goes to maximum. After confirming the compression, tighten the plug back and give it a trial start. Everything should be running smoothly.

Rebuilding Stihl MS 250 carburetor:

The Stihl MS 250 carburetor has two different sides. Side A is the fuel pump side of the carburetor. This side pumps fuel from the fuel tank through the fuel line to the metering side of the carburetor. Side B is the metering side of the carburetor. This side supplies fuel to the jets in the carburetor so the saw idles properly. Functionally, this is the side that allows the saw to accelerate to full throttle instantly whenever the throttle is activated [pulled]. This side has an additional role as well, it maintains fuel to the chainsaw motor at full throttle regardless of the position of the saw.

The Stihl MS 250 carburetor is equipped with diaphragms and gaskets. Their job is to help it pump and metre the fuel by crankcase impulse. Every time the piston goes up and down, it creates a vacuum and pressure in the crankcase. The carburetor uses this pulse via a pulse line connected to the crankcase or through the carburetor intake to get the pulse needed to properly make the carburetor function.

A diaphragm and gasket with a cover plate screwed to the carburetor is on the metering side of the Stihl MS 250 carburetor. The amount of fuel allowed to enter the metering lever side of the carburetor is controlled by the metering diaphragm. The diaphragm and the fulcrum [meter lever] are either connected or just touching. Fuel therefore exits the metering side of the carburetor through the jets in the carburetor, creating an atmospheric pressure [14.7 psi] that pushes the diaphragm in letting more fuel in. As the fuel rises to fill the metering lever side of the Stihl MS 250 carburetor, the inlet needle valve closes the fuel off from the fuel pump side of the carburetor. The needle valve goes into the body of the carburetor. This is then fastened to the metering lever fulcrum. The metering lever fulcrum has a spring under the opposite side of the needle valve. The function of this spring is to keep pressure on the needle valve when closed.

On the metering lever side of the Stihl MS 250 chainsaw carburetor there are two sides, a low side and a high side. When the saw starts to rev up, the low side controls idle and acceleration . The amount of fuel the saw will receive at full RPM is controlled by the high side. Some carburetors will have 2 adjusting screws, one for the high side and one for the low side . There is also an idle screw which makes contact with the throttle shaft to control idle speed along with the low side of the carburetor. Note that some carburetors have just one adjusting screw and the other side is prefixed and non-adjustable. Some may also have no adjusting screws (except the idle screw) to preset or pre-jet the carburetor.

Indicators that your carburetor is developing problems include the chainsaw getting bogged down. Continuously having problems to start or hard starts, and when it does start, the bogging is persistent. You will notice you have to continually adjust the carburetor for it to run properly.

Here are step by step instructions on rebuilding stihl MS 250 carburetor:

- To access the carburetor you have to go through the air filter. The air filter on the Stihl MS 250 has an orange plastic cover. A black knob is visible. Turn this knob to take the cover off.

- The air filter comes into view once the cover is taken off. The air filter is held in place by a stand that is secured by two bolts each 8mm. Unbolt these 8mm bolts and the whole piece will slide off.

- Now you’re face to face with the carburetor. You’ll see a breather. Take this breather off. Pull at the top rubber piece to take it out of the way.

- Next you’ll see the choke lever. To release the rod, just push forward on the lever and it slides out. It is important that you remember the position of the off-switch. You push the lever forward and it pops out of its spot. Hold the spring up while doing it. Once it pops out you pull it out of its retaining spot on the opposite side.

- Now you need to take the handle off. Turn the saw on its side to access the securing screw. Once the screw is off, you lift the handle off from the back. It should pop out in the front. When you take the black handle off, it will release the spring and the safety. Confirm everything is still there. Keep an eye on how the parts are arranged in place because you’ll need that lined up in order later.

- Next is to take the fuel throttle rod and release it. It’s captured by the trigger in the handle. Use some pliers and pry it out. Try not to mess or break anything. Once it gets loose, turn it clockwise and it will come out easily.

- Now your carburetor is ready to come off. You just pull it out. Get it off its mounting studs. Once off, you need to take the bottom and top plate off. The screws are standard. Inside, you’ll see the diaphragm and the gasket. Take the screen out and while at it be careful not to scratch the carburetor. Set them aside as you won’t be needing them.

- Next you need to take the needle out. This is a bit tricky. Using the relevant screwdriver, press down with your thumb over the top because it is spring loaded. Open it up. Release it slowly once open because of the spring. Remove the spring and needle.

- Now you’re ready to clean your carburetor. Soak it in acetone. Take compressed air and blow the jets out throughout the carburetor. Make sure you clean the outside and the inside while trying not to blow junk into it. That should make it clean.

- We are ready to start rebuilding Stihl MS 250 carburetor. Get your Stihl MS 250 carburetor rebuild kit. It’s advisable to check the package is in good condition and no seals have been broken or tampered with before you open. Inside the kit are the diaphragms, gaskets, needle, and a screen. Make sure not to mix the old and new parts.

- Back to the carburetor, put back the new screen inside the carburetor. Put the bottom plate on and get it covered up. Put the gasket on. Put the diaphragm on. You’ll see a retaining stud on each side.Pull your throttle lever back, because your throttle set screw is in the way. Pulling the throttle lever back clears the way. Once fitted, release the throttle lever. Pinch them together and screw it back on while putting pressure on it.

- Next put the needle in followed by the spring in its seat. This is usually tricky since the spring needs to be trapped in place so it doesn’t jump right out.

- Put the diaphragm on the plate. It’s got a locking tab in one corner that ensures it can only go in one way. Make sure the diaphragm and gasket are in line when they go in. Screw them back in. And that’s it. Carburetor is done.

- Get a hold of the saw and put them back together. For proper alignment, the two adjustment screws on the carburetor should be facing to the right. Mount your gas line, mount the carburetor back on its studs and get your choke put back together. To properly fit the choke, you should lift up on your spring, insert the retained end into its hole until the choke is under the spring. Put it in the retaining hole under the tab and push it all the way until it lines up with its notch slot. Then push it down. It should pop over the notch in its choke position. Confirm that your off button is in its correct position.

- Fit your contact wire back into its slot. It should go into a bracket. When you turn the switch to the off position it should make contact with your sprinkler.

- Next fit in the choke rod. Push the choke lever forward, there’s a hole in the bracket, you slide the choke rod into it and line the choke lever up with the rod and release it and it’s captured.

- Now get the throttle rod. Do the same thing we did when we took it off but opposite. Find the hole and the throttle lever, turn it counter clockwise, line it up with the notch in the trigger. Be gentle not to break the plastic. So now the throttle, choke, on and off switch are in place.

- Next put the breather back in. When putting the breather back in, note the holes for the adjustment screws. Slide the bottom hole into the bottom adjustment screw, it has a retaining slot inside the saw. It goes in when you get it all lined up.

- Put the handle cover back on. Slide it back under the front retainers. Make sure your safety comes out. Push the handle cover down, turn the saw on its side and screw the handle tight.

- Put the air filter housing back on. It should slide in on its studs. Make sure it’s all pushed down. Secure it with its 8mm nuts. Fit the air filter in its housing. Followed by the orange outer cover. It should just slide down and pop in. Turn the black knob to secure and lock the cover.

You have just completed rebuilding Stihl MS 250 carburetor.

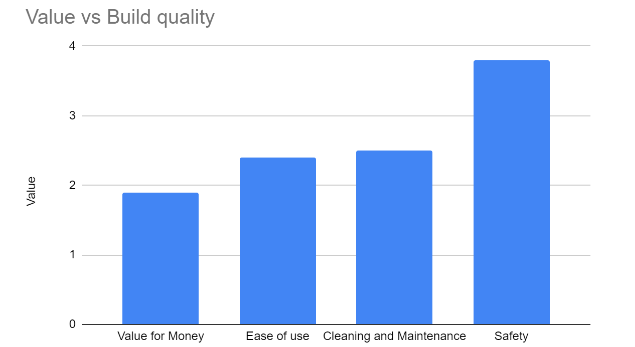

Stihl MS 250 product review showing performance parameters. Stihl MS 250 | ProductReview.com.au

Stihl MS 250:

The Stihl MS 250 is a chainsaw designed for cutting firewood. This Stihl chainsaw is considered to have a great power-to-weight ratio. Featuring a 2-cycle engine that delivers 1.5 brake horsepower, it is relatively easy to use and is an ideal tool for tackling clearing and clean-up tasks as well as for cutting through small limbs and trees. The Stihl MS 250 chainsaw has the capacity to handle large jobs. It has a small, compact design and lightweight body frame. This chain saw is designed for a job site that values manoeuvrability and portability. MS 250 | High-Performance Compact Chainsaw | STIHL USA. Two bar lengths are available: 16 inches and 18 inches. It comes with a two-year factory warranty.

Frequently asked questions:

- 1. What does the MS mean in Stihl chainsaws?

The MS in Stihl chainsaws stands for Motorsäge. It means chainsaw in german.

- Is it bad for a chainsaw to run only for a short period of time? My step dad insists that the chainsaw “needs to run without stopping” rather than being started and stopped as I adjust logs for cutting. I think it’s fine but checking here just in case

It doesn’t make sense to stop the saw if the period is short, for example 20 seconds. For periods longer than a minute it is advisable to stop. Constantly restarting the saw takes time and energy, and puts more wear on the starter. It is easier and quicker to work by doing a load of cutting, a load of tidying up with the saw stopped, then another load of cutting.

- What are the most common reasons a chainsaw won’t cut?

The most common reason why a chainsaw won’t cut accurately is a dull cutting chain. Sharpen or replace the chain. It may not have the proper amount of tension. The adjustment screw may be too loose, for instance, making the chain not make good contact with the wood.

In light of this information, I conclude by noting that the Stihl chainsaw remains the number one selling chainsaw brand in the US. Buyers tend to prefer the Stihl chainsaw for personal use because they are cheaper and easier to maintain.

19 MINUTES

ESTIMATED TIME DESIGNING AND UPLOADING THIS ARTICLE

10 HOURS 26 MINUTES

ESTIMATED TIME RESEARCHING AND WRITING THIS ARTICLE

You Might Also Like

Ninja Professional Kitchen System 1500 Watts

The kitchen, regardless of its size, remains one of the most important places in the house, and people have always known that. We’re talking about where cooking activities are performed, and although not too many people like being in there, preparing meals is just as

What Size Air Conditioner Do I Need?

That Pesky Question It’s the middle of the summer when your air conditioner breaks and the search for a new one begins. No sooner are you online browsing before the same question hits every time: what size air conditioner do I need? This question is

How To Pack Kitchen Appliances For Moving?

I bet you didn’t know that it is necessary for you to take an inventory of the items you are moving to a new location before you commence your packing. You may not be aware also that boxing up smaller appliances and labeling them according to the items they

Are Blenders Really Good For You?

There has been a lot of talk about blending recently and people all over the web are asking and posting questions about blenders. Are they really good for you? Our expert team members have come up with the answers so you can get some peace

The Best Ways to Clean a Nuova Simonelli Espresso Machine

Espresso coffee is a more concentrated form of coffee. Although it is made from the same beans used for traditional coffees, it is more concentrated. It is thicker, and higher in caffeine. The expresso is a special coffee served in Italy, though its fame has

Black Stainless Steel Frigidaire Dishwasher Review

Black stainless steel dishwashers are fast becoming very popular, thanks to their sleek and beautiful designs. If you’ve been looking to explore your options on the market for a new dishwasher, you will find our black stainless steel Frigidaire dishwasher review particularly helpful. Kitchen appliances

TOP-RATED APPLIANCES PACKAGES – TOP 5 PICKS

In this article, we’ll be exhaustively discussing some of the top-rated kitchen appliance packages money can get you out there. We’ll be looking at packages from brands like Frigidaire, Samsung, and the likes. You’ll also be able to know how much each package costs and

How to Use a Stovetop Grill Pan?

Stovetop grill pans don’t often get the attention they deserve because they’re not seen as an important part of the kitchen, yet, in reality, that’s what they are. If you have a stovetop grill pan but you have no idea how to get the best

Vitamix immersion blender review

The idea of using immersion blenders in the kitchen is almost non-existent because people don’t just see what they do. After reading our detailed Vitamix immersion blender review, we hope your opinion about immersion blenders changes. Blenders have always been a necessary component of any

Top 3 Best Electric Water Heaters For Cold Climates

Electric tankless water heaters have gained prominence in recent years, displacing their traditional counterparts. If you’re looking for the best electric tankless water heaters for cold climates, read on to find out more. In the face of frigid weather, the last thing you want to